Drywall is comprised primarily of gypsum which is comprised of water and mineral. When gypsum- or drywall-covered walls are exposed to fire, water is released in the form of steam. The steam acts as a thermal barrier. Simplified, the thermal barrier is only slightly hotter than boiling water and at a temperature significantly lower than the temperature in which wood ignites. Thus to certain degrees, drywall is fire resistant. Common whiteboard is less fire resistant though than some special classes of more fire resistant drywall materials or combinations of drywall.

There are essentially three types of drywall as it relates to fire resistance. One is regular drywall of regular core. Another is Type X drywall and the third is Type C drywall. As mentioned, all drywall is somewhat fire resistant. It is essentially water and rock – which is hard to burn. Type X drywall is different from regular drywall or white board in that it contains additives included during production which enhance its fire-resistive properties. The basic component added to Type X to give it superior resistance is fiberglass. Type C gypsum wallboard is the most fire resistant type of drywall. The composite of Type C drywall varies, but it is as a rule, more fire resistive than white board and Type X drywalls. The most important characteristic of drywall, according to fire officials, is that it will not burn. It has been shown that as the number of gypsum products and fire-resistant building materials has increased, the number of fire deaths in the US in recent years has declined. With its gypsum core, as explained above, the drywall actually emits steam when exposed to fire which retards transfer through the wall to the framing. The process of slowing down the fire provides extra time to evacuate a room or building.

Now fire resistant Type X and C drywall may look like white board drywall, but these sheets of drywall are more effective barrier against fire than regular drywall. Type X drywall must provide at least 60 minutes of fire resistance for 5/8″ thick drywall and at least 45 minutes of fire resistance rating for 1/2″ Type X drywall. When Type X sheet rock is made ¾” thick it has a two hour fire resistance rating.

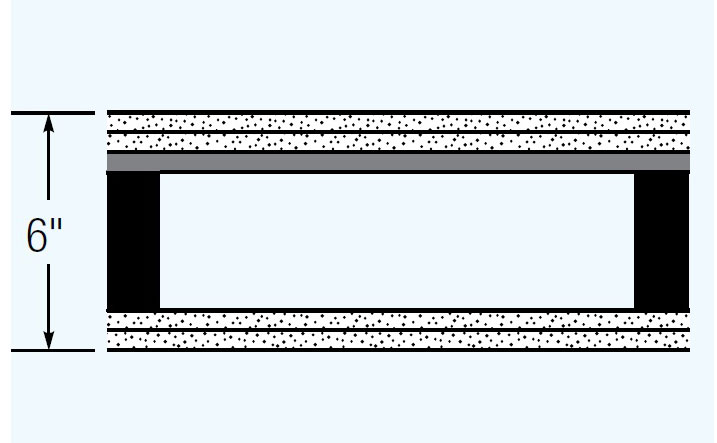

The most commonly used thickness for this wallboard or drywall is the 5/8 inch fire-resistant wallboard panels. It is available in 8 foot, 10 foot, and 12 foot lengths and has a maximum approved framing spacing of 24 inches on center stud-to-stud.

The use of fire resistant drywall is dictated by local building codes. They call for use of fire resistant drywall as firewalls in furnace or utility rooms, attached garages, and ceilings and walls that separate units in condominiums and apartment buildings. Because fire ratings depend on the complete installation the wallboard – studs, nailing pattern, and other factors are taken into account to determine a fire rating. A professional local drywall contractor will have a complete knowledge of these issues. Remember to pay attention to what the professionals say. When it is a matter of safety, listen to a qualified drywall contractor and your local building officials.